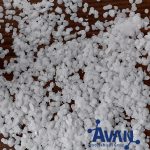

Styrene Butadiene Rubber

Product

Styrene Butadiene Rubber (SBR 1723, 1721, 1705,1712, 1500,1502, 1507)

Description:

Styrene butadiene rubber is a type of synthetic rubber that is also the most common one. In terms of demand, it is the most popular type of synthetic rubber worldwide. Moreover, it’s the cheapest type of synthetic rubber.

Copolymerization of Styrene and butadiene monomers in the presence of a catalyst produces styrene butadiene rubber. The composition resulting from this reaction contains 25% styrene and 75% butadiene. It also has the most similarity to natural rubber. In addition, it offers numerous advantages over natural rubber in terms of performance, consistency, and availability. One of its prominent features is that it is more economical than natural rubber.

When styrene monomer (C8H8) and butadiene monomer undergo copolymerization, they combine to form the SBR polymer chain. The styrene units provide rigidity and strength to the polymer, while the butadiene units contribute flexibility and elasticity.

Styrene butadiene rubber is classified into different types and grades based on their polymerization method, polymer structure, and specific properties. Some common types of SBR are as follows:

- Emulsion SBR (ESBR): The emulsion polymerization process produces ESBR, which yields a polymer with a high styrene content.

- Solution SBR (SSBR): SSBR is manufactured via the solution polymerization process, resulting in a polymer with a high butadiene content.

- Oil-Extended SBR (OSBR): It contains a high concentration of extending oil, typically around 30-50% by weight.

- Styrene Butadiene Latex (SB Latex): It’s a water-based dispersion of SBR particles.

- High Styrene resin (HSR): It has higher styrene content, exceeding 50%.

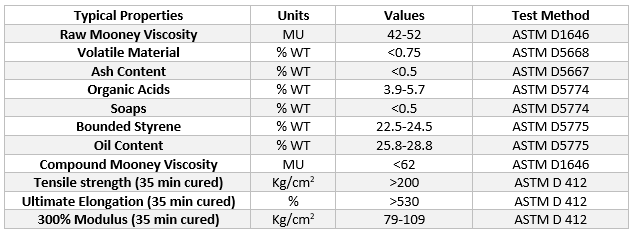

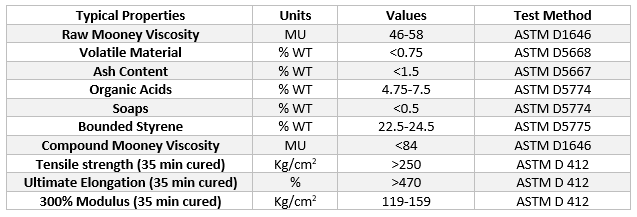

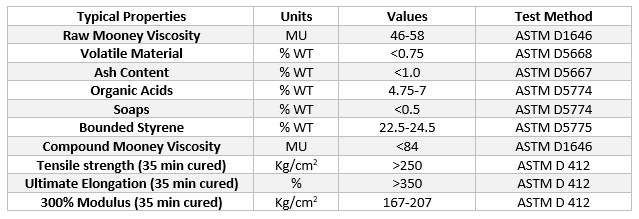

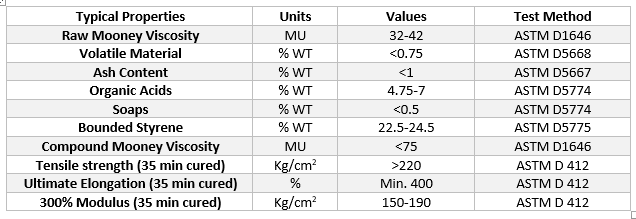

The numbers that are associated with SBR grades often indicate the styrene content of the polymer and can reflect variations in properties such as hardness, tensile strength, and viscosity. Oil-free grades of styrene butadiene rubber include SBR 1500, SBR 1502, and SBR 1507. Oil-extended grades of styrene butadiene rubber include SBR 1712, SBR 1705, SBR 1721, and SBR 1723.

Styrene Butadiene Rubber Features and Advantages:

SBR has high resistance to abrasion and friction. This property improves durability and protects against wear and tear.

Styrene butadiene rubber shows excellent resistance to weathering, Such as exposure to sunlight, ozone, and other environmental factors. It’s a great property for outdoor applications.

Due to its enhanced adhesion, this rubber bonds well with various surfaces.

Its resistance to oil and chemicals is moderate, making it suitable for certain industrial applications where contact with oils, fuels, and chemicals.

Styrene butadiene rubber has satisfactory electrical insulating properties, making it suitable for applications in the electrical industry.

SBR is an economical rubber. In addition to its performance and versatility characteristics, it is also affordable.

Its raw materials like styrene and butadiene, are readily available, making it an easy-to-find product.

Styrene Butadiene Rubber Uses and Applications:

- SBR finds a lot of applications in the production of tires, particularly in tread compounds. It also has applications in other automotive components, such as gaskets, hoses, belts, and seals.

- Styrene butadiene rubber has applications in the manufacturing of shoe soles and outsoles.

- It acts as a base polymer in the formulation of adhesives and sealants. It offers excellent adhesion to various substrates, including metals, plastics, and wood.

- Styrene butadiene rubber has applications in the construction industry. It is available in the production of roofing membranes, waterproofing materials, and sealants.

- SBR acts as a coating for paper and cardboard. It improves surface properties, such as water resistance, printability, and smoothness, enhancing the overall quality and performance of coated papers.

- Styrene butadiene rubber finds applications in the manufacturing of conveyor belts. It ensures the durability and longevity of conveyor systems.

- It’s available in the production of various industrial rubber products, including gaskets, seals, hoses, and O-rings.

- Styrene butadiene rubber acts as an insulating material in electrical cables and wires. It provides electrical insulation and protection against environmental factors, enhancing the safety and performance of electrical systems.

- SBR is available in the manufacturing of rubber sheets and mats. These products find applications in commercial, industrial, and residential settings, offering properties such as impact resistance, anti-slip capabilities, and durability.

Styrene Butadiene Rubber Packing:

Fumigated wooden box pallet in 1260 KG

Styrene Butadiene Rubber Storage and Transport:

- Store it in a cool and dry place

- Protect it from sunlight.

- Avoid extreme temperatures

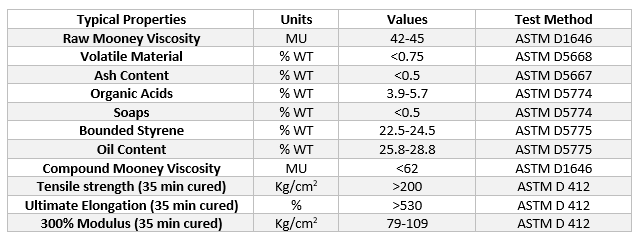

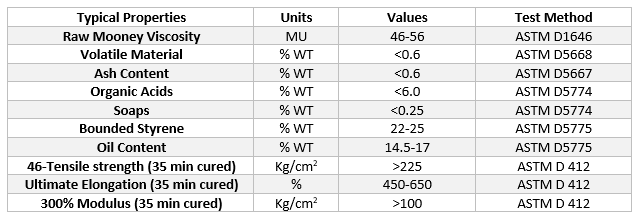

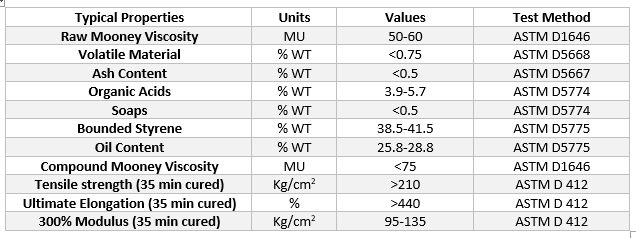

Styrene Butadiene Rubber Technical Information:

related products:

Plastic compounding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Paraffin Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Polyethylene Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cracked Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.