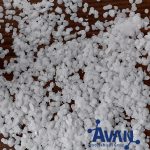

Carbon Black

Product

Carbon Black

Description:

Carbon black is a complex mixture of carbonaceous materials that can vary in composition and structure depending on the production process and intended applications. It’s a type of finely divided carbon. Incomplete combustion of hydrocarbon-based materials such as coal, oil, or natural gas produces this product.

This process is called “carbon black manufacturing” which the combustion process occurs in a furnace or reactor, where hydrocarbon feedstocks are burned with a limited supply of air. The next step to produce it is to remove impurities.

Carbon black, also known as carbon pigment, is distinct from “black carbon”. Black carbon significantly contributes to air pollution and harms human health and the environment, while carbon black is an industrial substance.

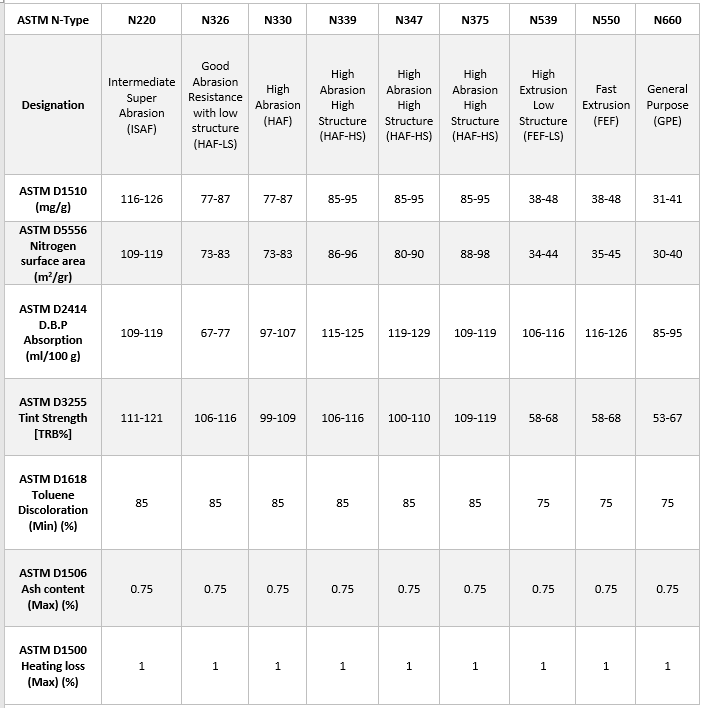

The American Society for Testing and Materials (ASTM) has established a classification system for carbon black based on its physical and chemical properties. ASTM grades, such as N220, N330, N550, and N660, indicate different levels of structure, surface area, and other characteristics. The N-grade System is a reference for specifying it in various industries.

The number represents the nominal surface area of the carbon pigment in square meters per gram (m²/g). The higher the N-number, the larger the surface area of the carbon pigment particles. The surface area of this product is an important parameter that influences its performance and functionality in different applications.

Carbon Black Different Types:

It is categorized by production method, particle size, and surface properties. These are some common types:

- Furnace Black: combustion of hydrocarbon feedstocks in a furnace or reactor produces this type. It has a wide range of particle sizes and structures. It exhibits great reinforcing properties.

- Channel Black: the partial combustion of natural gas or oil in a channel process produces channel black. It has a unique particle structure, with a high degree of aggregation and a lower surface area than furnace black.

- Thermal Black: the controlled decomposition of hydrocarbons at high temperatures produces thermal black. It has a relatively high structure and low surface area.

- Acetylene Black: the thermal decomposition of acetylene gas at high temperatures produces acetylene black. It has a unique structure with small, highly crystalline particles. Acetylene black exhibits excellent electrical conductivity.

- Specialty Carbon Black: carbon pigment goes through specialized processes to meet specific requirements. These include high-purity carbon pigments, which makes them suitable for applications where purity and cleanliness are critical.

- Lamp Black: the incomplete combustion of oils or resins produces this type. It has the lowest structure and surface area among different types of carbon pigment.

- Hard Carbon Black: it has a high degree of structure, larger particle size, and greater surface area, which provides good reinforcement properties.

- Soft Carbon Black: it’s also known as low-structure carbon black and has smaller particle sizes and lower structure. It has improved dispersion and surface smoothness. It also provides fine texture, colour development, and surface finish.

- Masterbatch Carbon Black: pre-dispersing or pre-blending carbon pigment with a carrier polymer, such as polyethylene or polypropylene produces this type. This type simplifies the process of incorporating carbon pigment into various materials, such as plastics.

- P-Type Carbon Black: it’s a specific classification that has a high electrical conductivity.

Carbon Black Features and Advantages:

Carbon black has an intense black colour due to its high carbon content and light-absorbing properties.

Its particles exhibit a unique structure, typically spherical or acicular in shape, with a high surface area-to-volume ratio. This structure contributes to its reinforcing and pigmenting properties.

Carbon black particles vary in size, typically ranging from a few nanometers to several hundred nanometers in diameter. The particle size distribution can affect the properties and performance of this product in different applications.

It has a complex surface chemistry, with various functional groups present on its surface. These surface groups can influence its interactions with other materials, such as polymers, leading to improved reinforcement and dispersion.

Due to its high carbon content and unique structure, it exhibits excellent electrical conductivity.

When incorporated into rubber compounds, carbon black enhances the mechanical properties of the resulting products. It improves tensile strength, tear resistance, abrasion resistance, and overall durability.

Carbon black has strong UV absorption properties, making it effective in providing UV protection in various applications. It helps prevent degradation caused by exposure to sunlight, extending the lifespan of materials.

This product is chemically inert, meaning it does not readily react with other substances. This quality contributes to its stability and compatibility with different materials.

Carbon Black Uses and Applications:

- Carbon black acts as a reinforcing filler in the production of tires, conveyor belts, hoses, and gaskets. It improves the strength, elasticity, and wear resistance of rubber compounds.

- Carbon pigment finds applications in the plastic industry as an additive. It enhances plastic’s mechanical properties, such as strength, stiffness, and impact resistance. It is used in the production of automotive parts, pipes, cables, films, and other plastic products.

- It has applications in the production of conductive coatings, electrodes, batteries, and electronic components.

- This product acts as an additive in batteries, such as lithium-ion batteries.

- It finds applications in water and air filtration systems. This helps remove impurities and contaminants due to its high surface area and adsorption properties.

- Carbon black is a key ingredient in the manufacture of inks, particularly for printing applications. It provides intense black colour, opacity, and UV stability. Moreover, it has applications in coatings, including paints, varnishes, and pigments, to achieve deep black shades and improve durability.

- Carbon Black acts as an additive in the production of adhesives and sealants. It enhances their strength, adhesion and resistance to environmental factors. This material also improves the durability and performance of these materials.

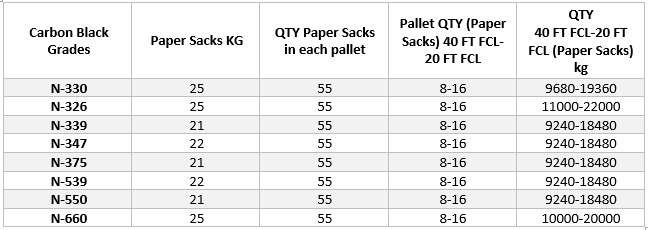

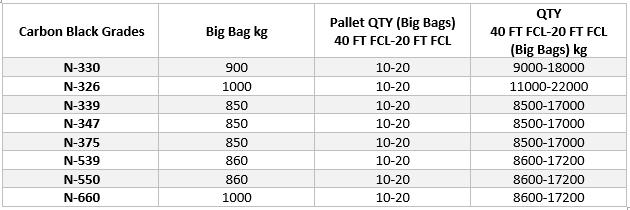

Carbon Black Packing:

Carbon Black Storage and Transport:

- Store it in closed containers

- Keep it away from exposure to high temperatures, open flame sources and strong oxidizers

- Keep it in a dry and clean environment

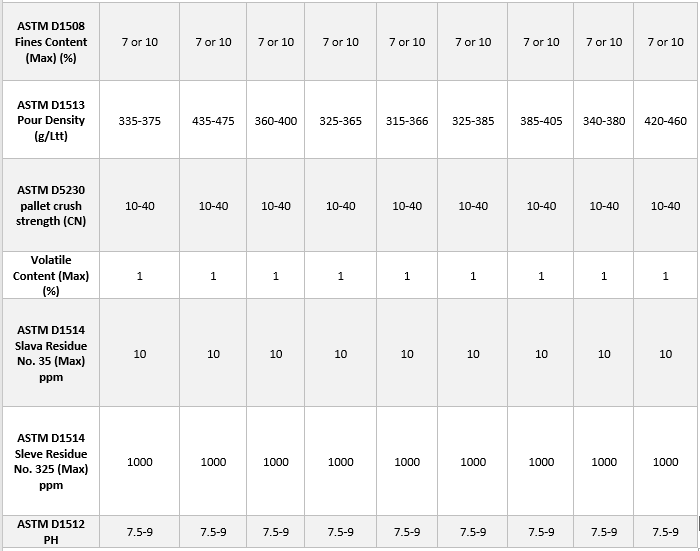

Carbon Black Technical Information:

related products:

Plastic compounding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Paraffin Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Polyethylene Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cracked Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.