Polybutadiene Rubber

Product

Polybutadiene Rubber (PBR 1220C, 1220, 1202)

Description:

Polybutadiene rubber is a type of synthetic rubber. It appears as a white or slightly yellow bale with a slight odor. Its chemical name is Polybutadiene, meaning it’s formed through the polymerization of butadiene monomers (C4H6). The polymerization process links multiple butadiene monomers together. As a result, it forms a long-chain polymer with repeating units of butadiene.

PBR grades can vary in terms of their polymerization process, monomer composition, molecular weight, and other additives. These variations can result in differences in the physical properties and performance characteristics of the rubber. Different grades of PBR are PBR 1220C, PBR 1202, and PBR 1220.

Grade 1202 polybutadiene rubber has a low gel percentage and is suitable for HIPS production. Polybutadiene rubber with grades 1220C and 1220 are used in the production of car tires, conveyor belts, shoe soles, cables and other plastic items.

The main raw material for this product is petroleum. Polybutadiene rubber itself has different types, such as high cis polybutadiene, lithium-based polybutadiene, and high trans polybutadiene. Based on specific needs, a particular type can be utilized.

After Styrene Butadiene Rubber, this type of synthetic rubber is the second largest volume by production. When it comes to elasticity, this type is the most elastic one among synthetic rubbers. PBR is commonly found in combination with other synthetic rubber types.

Polybutadiene Rubber Features and Advantages:

Polybutadiene rubber has a high resilience. It means PBR can quickly return to its original shape after deformation. In conditions where flexibility and elasticity are important, this property helps a lot.

Because of its low glass transition, polybutadiene wax remains flexible at low temperatures. This feature makes it suitable for applications in cold environments, such as seals and gaskets for refrigeration systems.

Polybutadiene rubber can withstand repetitive impact and friction, due to its high abrasion resistance. As a result, it’s a suitable material for products that are subject to wear and tear.

It shows excellent impact resistance, making it great for shock absorption applications.

Polybutadiene rubber also exhibits resistance to various chemicals, such as oils, solvents, and acids. This Is a useful property for applications in the automotive industry.

It has good electrical insulating properties, making it valuable in electrical applications. This property finds applications in the manufacture of wire and cable insulation, electrical connectors, and insulation for electronic devices.

Moreover, Polybutadiene rubber has excellent adhesion properties, that allow it to bond well with different substances.

Polybutadiene Rubber Uses and Applications:

- A combination of PBR and natural rubber is the best in manufacturing tires. It improves traction, wear resistance, and grip in tire treads. That is to say, it improves the overall performance, durability, and fuel efficiency of tires. About 70% of the total production volume of Polybutadiene rubber goes into sidewalls and treads in the tire industry.

- It finds applications in the production of shoe soles. As mentioned, it has excellent impact resistance and also it’s the most elastic type. These features provide cushioning, flexibility, and durability to shoe soles.

- Due to its sealing properties and chemical resistance, it has applications in sealing and gaskets to prevent leakage.

- It has applications in bumpers, mats, and shock mounts to protect against impacts and vibrations.

- In construction and automotive applications, it acts as sealing joints and gaps.

- Polybutadiene rubber has a huge application in the production of industrial belts and conveyor systems. Because of its high abrasion resistance, it provides a long lifetime and smooth movements to these heavy-duty products.

- Polybutadiene rubber acts as vibration dampers. When it comes to reducing vibrations and noise in the industry, these vibration dampers are crucial. Industries that use polybutadiene rubber as a vibration damper are machinery, automotive suspension systems, and construction equipment.

- PBR can be modified to produce adhesives and sealants that bond effectively to various substrates, including metals, plastics, and rubbers.

- It’s suitable for wire and cable insulation due to its electrical insulation.

Polybutadiene Rubber Packing:

Fumigated wooden box pallet in 1260 KG

Polybutadiene Rubber Storage and Transport:

- Store it in a cool and dry place

- Protect it from sunlight.

- Avoid extreme temperatures

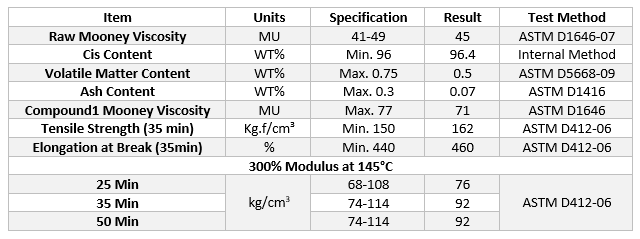

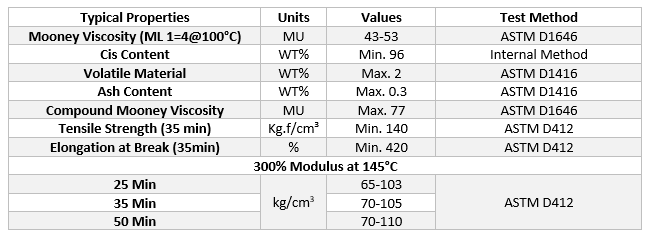

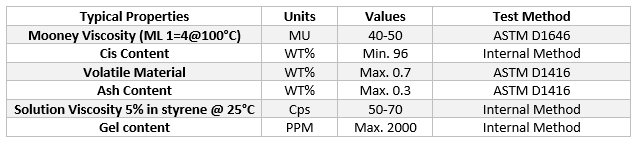

Polybutadiene Rubber Technical Information:

related products:

Plastic compounding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Paraffin Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Polyethylene Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cracked Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.