Polyethylene wax application and usage in different industries: emphasize on industrial grad of PE Wax

PE wax is a synthetic wax that is well known as polymer wax. Polyethylene wax is commonly used in various applications due to its excellent properties such as low melting point, excellent lubrication (external and internal lubricant), water resistance, chemical resistance, thermal stability, and non-toxicity. PE-Wax is a versatile and effective material for a wide range of applications.

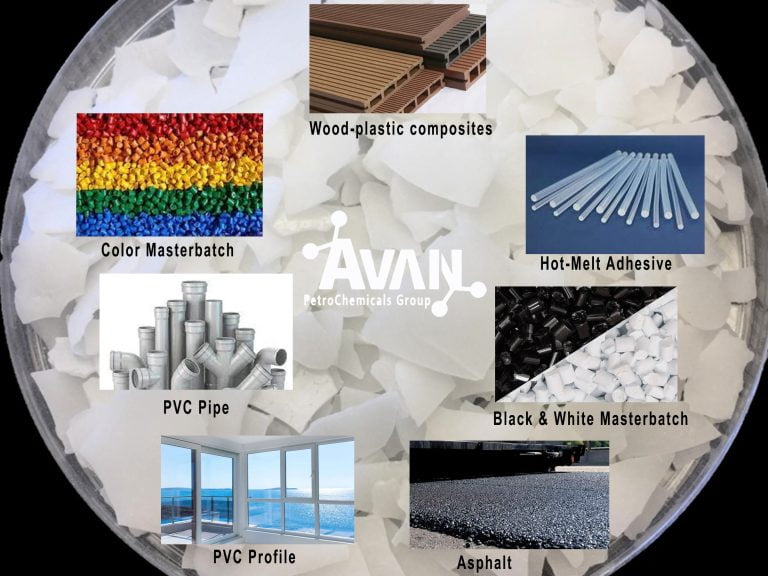

PE wax applications in different industries are as below:

1. Polyethylene wax in the packaging industry can improve the performance of various packaging materials, making them more durable, water-resistant, and easy to handle. PE wax can also help to reduce waste and improve the recyclability of packaging materials and making it an important material for sustainable packaging solutions. 2. Polyethylene wax is used as an additive in Coatings and Inks to improve scratch resistance, reduce the coefficient of friction, and improve gloss. PE-Wax can also help to improve the water-repellency of coatings. 3. Polyethylene wax is used as a processing aid in the hot-melt adhesives industry to improve adhesion, reduce viscosity, and improve the thermal stability of the adhesive. 4. Polyethylene wax is used as a lubricant in the PVC Processing industries to processing of PVC to improve flow and reduce the adhesion of PVC to processing equipment. 5. Polyethylene wax is used as a lubricant in the Textile Industry to improve the processing of fibers and to reduce the frictional forces between fibers. 6. Polyethylene wax is used in the rubber industry as an internal lubricant to improve flow, reduce tackiness, and improve the release of rubber compounds from processing equipment. 7. Polyethylene wax is used as a processing aid in the plastics industry to improve flow, reduce friction, and improve the release of plastics from molds. 8. Polyethylene wax is used in the printing industry to improve the rub resistance of printed materials and to improve the flow of ink. 9. PE Wax as a modifier in asphalt that can improve its performance and increase its lifespan (Improved durability), Increase resistance to deformation of asphalt, and make asphalt a popular choice for road construction and repair applications. PE Wax improves the resistance of the asphalt to deformation under high temperatures because polyethylene has a high melting point and can help to stabilize the asphalt at high temperatures. 10. Polyethylene wax is used in production masterbatch as a processing aid and performance enhancer. Color masterbatches are concentrated blends of pigments, additives, and other materials that are used to color or modify the properties of plastics. PE wax can help to improve the dispersion of pigments and other additives in the polymer matrix, leading to more uniform color and properties.

PE Wax can act as a lubricant in the masterbatch and improving flow and preventing sticking during processing. Anti-blocking agent of PE-Wax caused preventing the sticking of plastic films or sheets. PE wax can enhance the scratch resistance of plastics and make them more durable and long-lasting. PE wax can improve the gloss of plastics and make them more visually appealing.

We recommend you when using PE wax, it is important to follow the manufacturer’s recommended dosage and processing conditions to ensure optimal performance.