Polyethylene BL3

Product

Polyethylene BL

Polyethylene BL3 (Blowing) Features and Advantages:

Polyethylene BL3 Compound with 3% and 5% carbonate produced by AVAN Petrochemicals Group. By adding carbonate to BL3 resin (depending on the customer’s inquiry) this compound can improve the mechanical and thermal properties, such as stiffness, impact resistance, and heat resistance. Carbonate is a common additive used in polyethylene resins to modify their properties. The addition of carbonate can also improve the processing characteristics of the BL3 resin, such as reducing the processing temperature and improving the flow properties. This can result in a more efficient and cost-effective production process.

The resulting compound of BL3 resin with 3% carbonate can be used in a variety of applications, such as packaging, containers ranging from a few ml up to 10 litters, and Sheets for thermoforming. The specific properties of the compound will depend on the exact type and amount of carbonate used, as well as the processing conditions.

Polyethylene BL3 with carbonate can enhance the properties and performance, making BL3 HDPE compound suitable for a wider range of applications and improving its cost-effectiveness.

Polyethylene BL3 resin used can result in packaging that is lightweight, flexible, and cost-effective, making it a popular choice for a wide range of applications, such as food packaging, pharmaceutical packaging, and industrial packaging that is commonly used in the manufacturing of blown film products. Blown film is a process where plastic is melted and extruded through a circular die to form a tube-like structure. The tube is then inflated like a balloon and stretched to form a thin film.

Polyethylene BL3 is a High-density polyethylene (HDPE) in different types of polyethylene resin that is typically used in applications where higher stiffness, strength, and chemical resistance are required. HDPE is commonly used in the production of pipes, bottles, and containers, among other things. BL3 polyethylene blowing resin is a versatile material that can be used to produce a wide range of blown film products with different properties and characteristics.

Polyethylene BL3 (Blowing) Application :

Small blow molding, such as for bottles and containers up to 5 liters, is a common application for Polyethylene BL3 resin.

Polyethylene BL3 resin is a low-density polyethylene (LDPE) resin that has a high melt index, which makes it suitable for use in the blown film process to produce thin films with good optical properties.

In the case of small blow molding, the resin is typically extruded into a parison or preform, which is then inflated using compressed air to form the final shape of the bottle or container. BL3 resin is well-suited for this process due to its excellent processability, good mechanical properties, and ability to produce films with good clarity and surface finish.

Polyethylene BL3 can also be used in the production of packaging for pharmaceuticals and surfactants, as it can provide good barrier properties to protect the contents from moisture and other environmental factors. The use of BL3 resin can result in packaging that is lightweight, flexible, and cost-effective, making it a popular choice for a wide range of applications.

Polyethylene BL3 Blowing Packing:

Polyethylene Granular HDPE AVAN packed in 25 kg pp bag on the pallet with the shrink.

Polyethylene BL3 Blowing Packing:

- To be stored and transported between +5°Ϲ and +35°Ϲ

- Keep from freezing

- It should be stored in a cold and dry place.

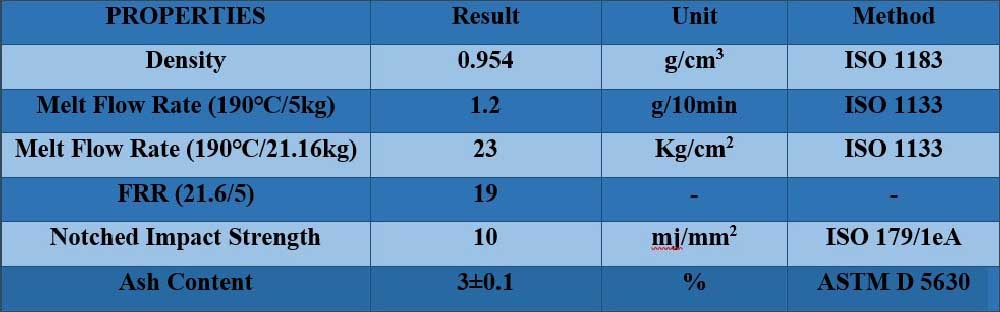

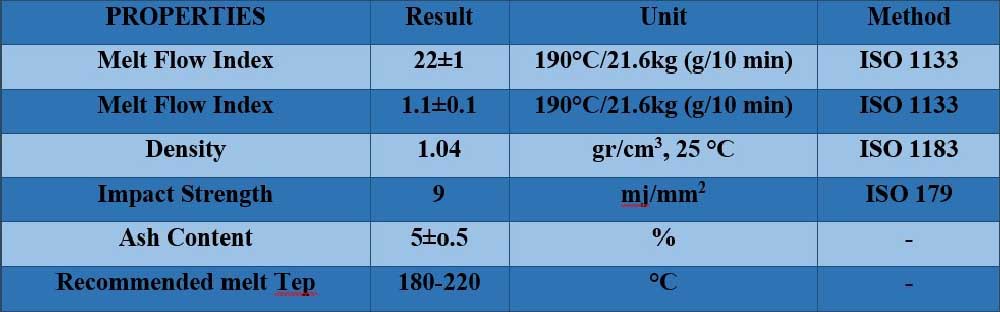

Polyethylene BL3 Blowing Compound with Carbonate Technical Information:

Calcium carbonate Filled HDPE compound 3%

related products:

Plastic compounding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Paraffin Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Polyethylene Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cracked Wax

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.